Mar. 23, 2023

Electronic Components & Supplies

Power transmission is one of the most crucial elements in any industrial process, and it requires a reliable and durable solution. In many industries, including construction, mining, and manufacturing, rubber flexible power cables are widely used for their high flexibility, resistance to harsh environments, and durability. These cables have a wide range of applications, from powering heavy machinery to connecting portable tools and lighting systems. This article will explore the features and benefits of rubber flexible power cables and why they are the preferred choice in many industries.

What are Rubber Flexible Power Cables?

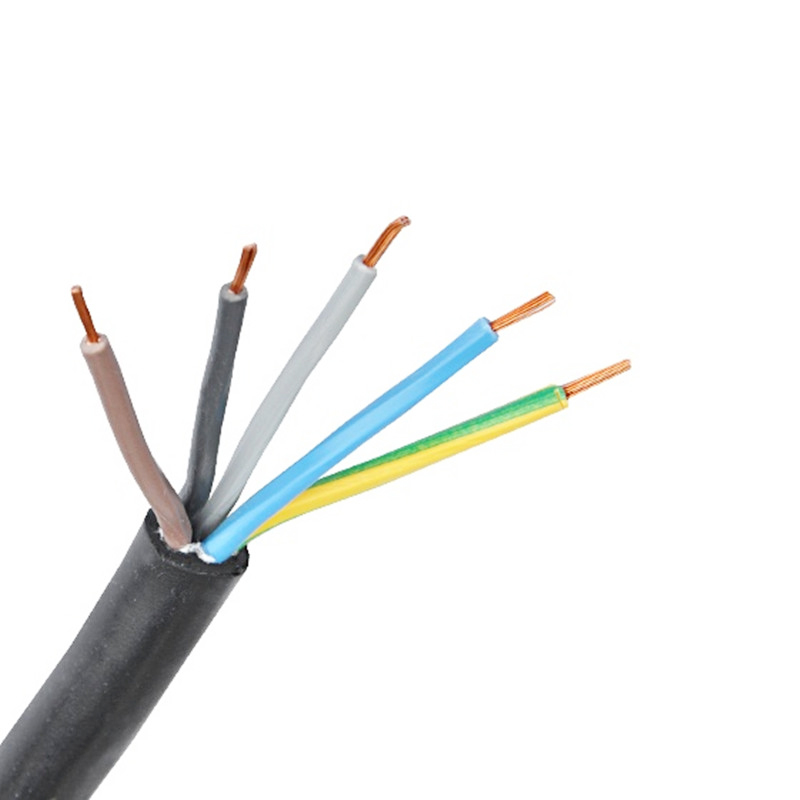

Rubber flexible power cables are made of stranded copper conductors covered with a rubber insulation and jacketing material. The insulation is typically made of ethylene-propylene rubber (EPR), which is highly resistant to heat, moisture, and chemicals. The jacketing material is usually made of neoprene, chloroprene, or a similar synthetic rubber that provides additional protection against abrasion and impact. These cables are designed to withstand extreme temperatures and harsh environments, making them ideal for heavy-duty applications.

Features and Benefits of Rubber Flexible Power Cables

Flexibility: One of the most significant advantages of rubber flexible power cables is their flexibility. The rubber insulation and jacketing allow the cable to bend and twist without cracking or breaking, making it ideal for use in tight spaces or around corners. This flexibility also makes it easy to install and move, which is essential in industries where equipment and processes are constantly changing.

Durability: Rubber flexible power cables are highly durable and can withstand extreme temperatures, moisture, and chemicals. They are resistant to oil, grease, and solvents, which is critical in industries where these substances are commonly used. The neoprene or chloroprene jacketing provides additional protection against abrasion and impact, ensuring that the cable can withstand harsh environments and frequent use.

High Voltage Capacity: Rubber flexible power cables are designed to handle high voltages and currents, making them suitable for heavy-duty applications. They are commonly used to power heavy machinery, such as cranes, excavators, and drilling rigs, as well as to connect generators and transformers to the power grid.

Versatility: Rubber flexible power cables have a wide range of applications, from powering heavy machinery to connecting portable tools and lighting systems. They are commonly used in construction, mining, and manufacturing industries, as well as in outdoor events, concerts, and festivals.

Safety: Rubber flexible power cables are designed with safety in mind. The insulation and jacketing materials are flame-retardant and self-extinguishing, which means that they will not catch fire or spread flames in the event of a fire. This is critical in industries where fire safety is a top priority, such as construction and mining.

Conclusion

Rubber flexible power cables are a versatile and reliable solution for power transmission in a wide range of industries. Their flexibility, durability, high voltage capacity, versatility, and safety features make them the preferred choice for many applications, from powering heavy machinery to connecting portable tools and lighting systems. Whether you're in construction, mining, or manufacturing, flexible power cables are an excellent investment that can improve the safety and efficiency of your operations.

Further reading:More articles:

RF Cable Assembly: The Backbone of Seamless Communication

USB-C Cables: Empowering Connectivity and Efficiency

What is the Difference Between SWA and Armoured Cable?

Understanding the Difference Between SWA and Armoured Cable

What Are The 2 Types of Fiber Optic Cable?

Importance of Clamps in AB Cable System

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )